What is Formply and Why is it Important in Large-Scale Construction Projects?

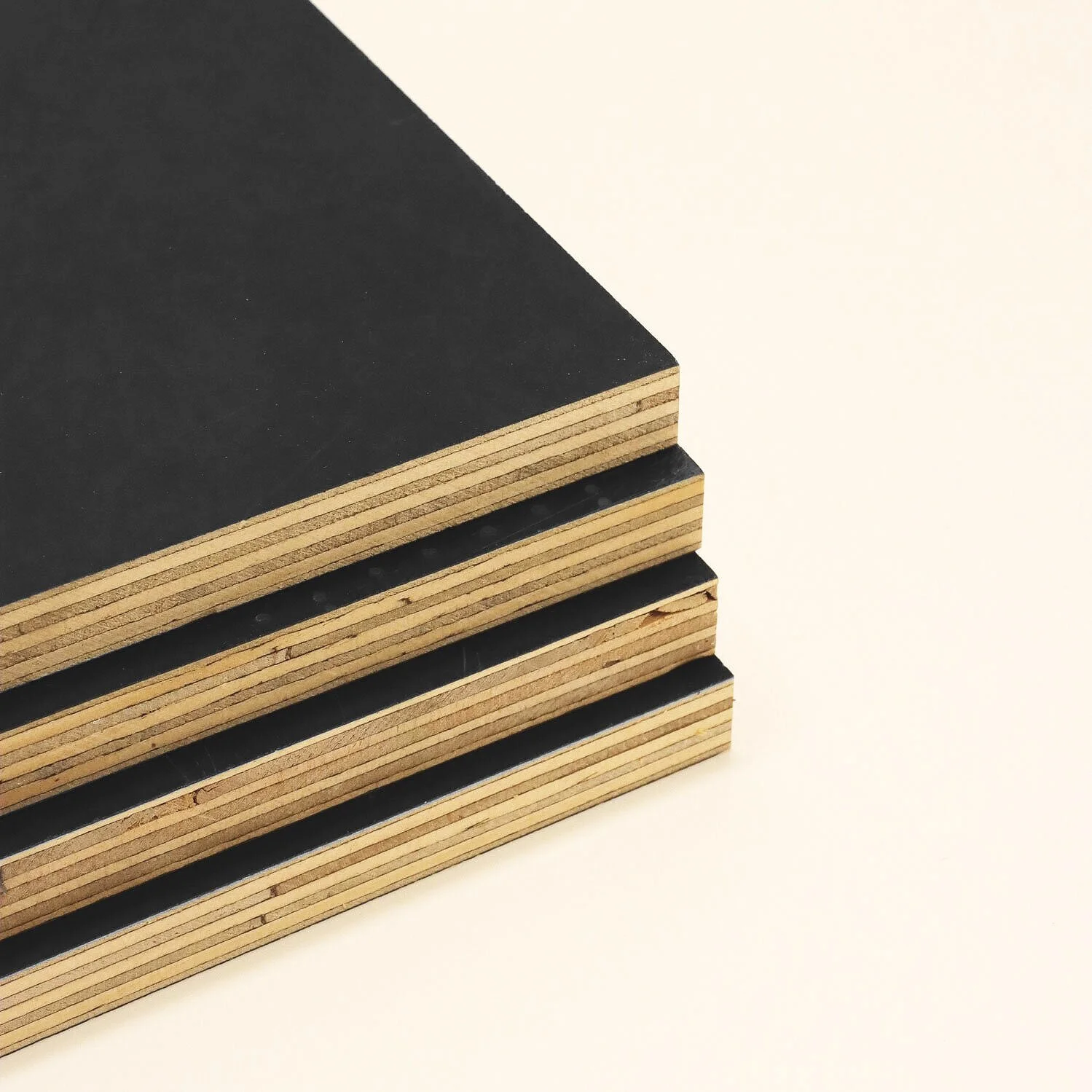

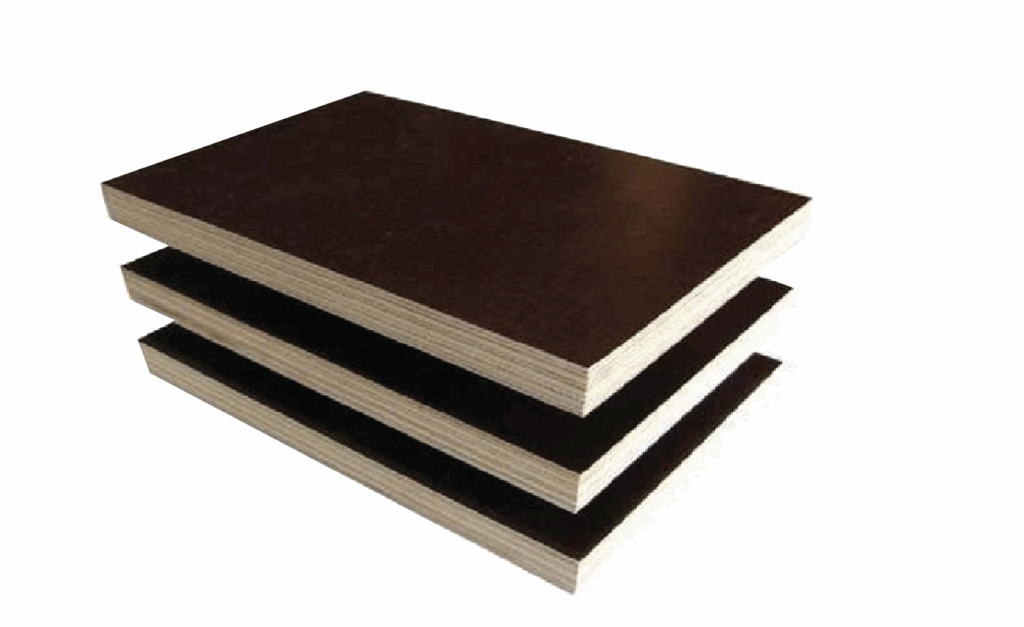

Formply is a specialized concrete formwork plywood engineered specifically for creating moulds that hold poured concrete until it sets and cures. Unlike standard plywood, this material features a phenolic resin film coating and sealed edges that enable it to withstand the intense pressures and moisture exposure inherent in large-scale construction projects.

The importance of Formply in major building developments cannot be overstated. When constructing high-rise buildings, bridges, or extensive infrastructure, builders rely on this engineered plywood for its strength, durability, and smooth concrete finish. Formply delivers consistent performance across hundreds of concrete pours, making it a trusted choice for large-scale construction projects.

- Structural reliability under heavy concrete loads

- Dimensional stability that maintains precise formwork shapes

- Surface quality that produces professional-grade concrete finishes

- Economic efficiency through multiple reuse cycles

This article explores the top 5 reasons builders choose formply for large-scale projects, examining how its unique properties translate into tangible benefits on construction sites. From superior strength characteristics to compliance with Australian building standards, understanding these advantages helps explain why formply has become the preferred concrete formwork plywood for demanding commercial and civil engineering applications. The material’s performance directly impacts project timelines, budgets, and final construction quality—making the choice of formwork material a critical decision for project success.

What Makes Formply Stronger and More Durable Than Standard Plywood?

Formply is stronger and more durable than standard plywood for several reasons:

- Specialised construction: Formply is made with multiple layers of hardwood veneer bonded together with phenolic resin. This creates a rigid panel that resists bending and warping under pressure. In contrast, standard plywood uses basic adhesives that break down faster under construction stress, leading to premature failure.

- Cross-laminated structure: Formply has a cross-laminated structure and high-density core, which are specifically designed for formwork applications. This allows it to maintain its shape and strength when supporting heavy loads of wet concrete.

- Superior load resistance: Formply can withstand concrete pressures exceeding 80 kPa without deflecting. It also has excellent impact resistance, wear tolerance, and edge strength, which further enhance its performance on construction sites.

- Protective coating: Formply has a phenolic film coating that creates a barrier against extreme conditions such as temperature fluctuations, chemical exposure from concrete additives, and physical abrasion from stripping operations. This prevents surface degradation and extends the lifespan of the material.

These factors combined make Formply the preferred choice for construction projects requiring reliable formwork solutions.

How Does Formply’s Moisture Resistance Benefit Builders?

Moisture resistant plywood like formply protects construction projects from water damage through its specialized phenolic film coating and sealed edges. This dual-layer protection system creates an impermeable barrier that prevents water penetration during concrete pours, unexpected weather events, and extended outdoor storage.

The phenolic resin film coating bonds to the plywood surface under high pressure and temperature, forming a waterproof shield that standard plywood cannot match. Sealed edges eliminate vulnerable entry points where moisture typically seeps into conventional materials, causing delamination and structural weakness. This makes formply superior to marine plywood—which handles water contact but lacks the structural integrity needed for formwork—and vastly outperforms MDF, which swells and disintegrates when exposed to moisture.

Weatherproof formwork capabilities deliver tangible benefits on site:

- Extended material lifespan: Panels maintain structural integrity through multiple concrete pours regardless of weather conditions

- Reduced replacement costs: Moisture damage accounts for 40-60% of formwork failures with standard materials

- Consistent performance: Dimensional stability remains unchanged even during wet seasons or humid climates

- Lower project delays: Builders avoid waiting for materials to dry or replacing damaged panels mid-project

The moisture resistance directly translates to fewer material failures, reduced waste, and predictable project timelines—critical factors when managing large-scale construction schedules and budgets.

Why Is Reusability an Essential Advantage of Formply?

Formply’s ability to withstand multiple reuse cycles makes it one of the most cost-effective construction materials for large-scale projects. Phenolic film-coated variants can be reused over 20 times whilst maintaining structural integrity, dramatically reducing the frequency of material replacements compared to standard plywood alternatives.

Cost Savings from Reusability

This exceptional durability translates directly into substantial cost savings. When builders can deploy the same formwork panels across numerous concrete pours, they slash material procurement expenses and minimise waste disposal costs. A single investment in quality reusable formwork plywood delivers value across multiple project phases, improving budget predictability and reducing financial risk.

Environmental Benefits

The environmental benefits complement the economic advantages. By extending the service life of formwork materials, construction teams significantly reduce their carbon footprint and contribute to sustainable building practices. Less frequent material replacement means fewer resources consumed, reduced transport emissions, and decreased landfill waste. Click here to learn about how does LVL Formwork compare to traditional timber systems?.

Efficiency Gains in Construction

Project efficiency gains become immediately apparent when formwork can be stripped, cleaned, and redeployed without degradation. Construction schedules tighten as teams spend less time sourcing replacement materials and more time maintaining momentum on critical path activities. This reliability proves particularly valuable on large-scale developments where delays cascade across multiple work fronts, making multiple reuse cycles a strategic advantage rather than simply a material characteristic.

How Does Formply Ensure a Smooth Concrete Finish?

Formply delivers exceptionally clean concrete surfaces because its smooth surface plywood construction creates minimal texture transfer during the curing process. The phenolic resin film coating provides a glass-like finish that prevents concrete from bonding to the formwork, resulting in architectural-grade surfaces that require little to no post-pour finishing work.

1. Eliminating Surface Defects

The clean concrete finish achieved with formply eliminates common surface defects like honeycombing, air pockets, and rough patches that plague projects using inferior materials. This precision matters significantly when constructing exposed concrete features, commercial facades, or infrastructure elements where appearance directly impacts perceived quality and property value.

2. Improving Formwork Quality

Concrete formwork quality improves dramatically because formply’s consistent surface prevents irregularities from transferring to the concrete. Builders working on high-rise developments, bridges, and public buildings rely on this predictability to meet strict aesthetic specifications without costly remedial work.

3. Accelerating Construction Timelines

The smooth surface also accelerates construction timelines by reducing labour hours spent on concrete finishing. Projects requiring painted or sealed concrete surfaces benefit particularly, as the uniform base eliminates extensive grinding or patching before final treatments can be applied.

4. Enhancing Structural Performance

For structural applications, the smooth finish contributes to better load distribution and reduces stress concentration points that rough surfaces can create. This dual benefit of aesthetic appeal and structural performance makes formply indispensable for quality-focused builders managing large-scale projects where both appearance and integrity cannot be compromised.

How Does Compliance with Construction Standards Influence Builders’ Choice of Formply?

Formply meets stringent Australian construction standards plywood requirements, making it a legally compliant choice for commercial and civil projects. This adherence to AS/NZS 2269 standards ensures the material delivers consistent performance across different construction environments, eliminating regulatory concerns that could delay project timelines.

Certified formwork materials provide builders with documented proof of quality and performance specifications. Formply’s certification covers critical aspects like load-bearing capacity, dimensional stability, and bonding integrity—factors that directly impact structural safety during concrete pours. Large infrastructure projects require this level of verification to satisfy insurance requirements and pass mandatory inspections.

The safety compliance benefits extend beyond paperwork. Formply’s sealed edges prevent moisture ingress and delamination, reducing the risk of sudden material failure during concrete placement. This feature protects workers from potential accidents caused by compromised formwork and prevents costly concrete blowouts.

Key compliance advantages include:

- Traceable manufacturing standards that document material composition and performance metrics

- Sealed edge technology meeting durability requirements for extended service life

- Phenolic resin coating conforming to chemical resistance specifications

- Structural integrity certification for high-pressure concrete applications

Builders working on government contracts, hospitals, and high-rise developments prioritise formply specifically because its certification streamlines approval processes. The material’s proven compliance record reduces project risk and demonstrates due diligence in material selection—essential considerations when managing multi-million-dollar construction budgets.

Moreover, compliance with formwork safety standards is crucial in the construction industry. As highlighted in this guide on formwork, adhering to these guidelines not only ensures worker safety but also enhances the overall quality and durability of the construction project.

Conclusion

The benefits of formply plywood make a strong case for its dominance in large-scale construction advantages. Its superior strength and durability ensure that structures can withstand heavy loads while reducing material failures. The moisture resistance feature protects investments from weather-related damage, significantly extending the lifespan of the material. Additionally, the reusability aspect transforms initial costs into long-term savings, with phenolic variants offering 20+ uses per sheet. The smooth finish quality eliminates expensive post-pour corrections, maintaining both aesthetic and structural standards. Furthermore, compliance with Australian regulations provides builders with certified peace of mind.

Ready to optimise your next project? These Top 5 Reasons Builders Choose Formply for Large-Scale Projects demonstrate why formply remains the industry standard for concrete formwork—delivering cost-effectiveness, efficiency, and quality that standard materials simply cannot match.

FAQs on Formply and Its Role in Large-Scale Construction Projects

Formply is primarily used as concrete formwork plywood — a material that creates moulds or forms to hold poured concrete until it sets and cures. It ensures concrete structures maintain their intended shape, strength, and finish during the construction process.

Unlike standard plywood, Formply is engineered with a phenolic resin film coating and sealed edges that make it resistant to moisture, pressure, and surface wear. It is specifically designed for heavy-duty construction applications and can be reused multiple times without losing structural integrity.

Builders choose Formply because it offers superior strength, moisture resistance, dimensional stability, and reusability. These qualities ensure reliable performance under high-pressure concrete pours, reduce replacement costs, and deliver smooth concrete finishes ideal for commercial or civil structures.

The phenolic resin coating creates a protective waterproof and chemical-resistant layer that prevents the plywood from absorbing moisture or deteriorating when exposed to concrete additives or weather. This coating also produces a smooth, defect-free concrete finish after demoulding.

Yes. High-quality Formply can be reused over 20 times, depending on proper handling and storage. Its reusability makes it a cost-effective and environmentally sustainable formwork solution, reducing both waste and long-term material expenses.

Moisture-resistant Formply prevents warping, delamination, and structural weakening, even in wet or humid conditions. This protection ensures consistent formwork performance, minimises project delays, and extends the lifespan of formwork materials used outdoors or on open construction sites.